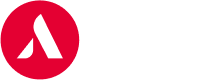

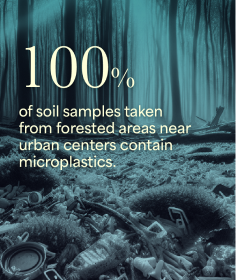

Millions of tons of plastic enter oceans and ecosystems each year, threatening wildlife and becoming an acute environmental issue. According to WWF every year, 4.8 - 12.7 million tons of plastic end up in the oceans.

Most packaging lasts 1-6 months before it ends up in the trash. The short lifetime of packaging generates a significant amount of plastic waste. According to statistics, 88.5 million tons of packaging waste was generated in Europe in 2017, and the number is increasing every year.

We present a solution to the plastic problem: the production of biopolymers, especially Polyhydroxybutyrate-co-3-hydroxyvalerate (PHBV), from cyanobacteria. This method enables the creation of fully biodegradable plastics.

BIO

Based

non degradable

Bio PE

Bio PET

Bio PA

Bio PTT

BIO

Based

Industrial

degradable

PLA

CONVENTIONAL

Fossil based

non degradable

PLASTICS

PE

PTA

PT

Fossil

based

Industrial

degradable

PBAT

PBS

Home

Compostable

PHA GreenUp

... in the fight against plastic pollution

Microalgae extrusion effectively sequesters CO2.

Microalgae products are fully biodegradable.

Production of microalgae products is infinitely scalable.

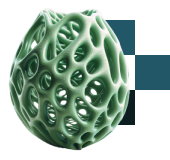

Microalgae properties suit items from plates to medical implants.

We aim to develop a pilot and demonstration plant that enables the production of PHBV from microalgae under non-sterile conditions. The entire process, from microalgae cultivation to extraction and processing, will be optimized.

Our ultimate goal is to achieve continuous and year-round production of microalgae biomass on an industrial scale, incorporating cell disruption and phase separation techniques.

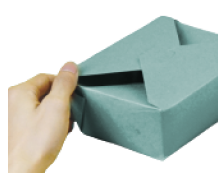

Foils

Plates

PACKAGES

MEDICAL

IMPLANTS

We present a solution to the plastic problem: the production of biopolymers, especially Polyhydroxybutyrate-co-3-hydroxyvalerate (PHBV), from microalgae. This method enables the creation of fully biodegradable plastics.